How to Prepare MDO Plywood for Sign Painting

Step-by-step guide to tools, materials and techniques to prepare MDO Plywood for exterior signs.

Hand-painted signs need a solid foundation if they're to go the distance for your customers. The selection and preparation of the board is the first step in this process. Here, Agustin at Magic 8 Ball Signs shares the lesson he learned from Doc Guthrie while studying on the Sign Graphics program at LA Trade Tech.

How to Prepare MDO Plywood Sign Blank—Doc Guthrie's Method

By Agustin McCord

Intended for sign tradespeople, this guide is also useful for illustrating to clients what their sign is made of, as well as how much time (and money!) goes into preparing a quality product. Additionally, a travelling tradesperson can share this information with a client who might wish to prepare their own sign blank for the purpose of cost or time efficiency.

What is MDO?

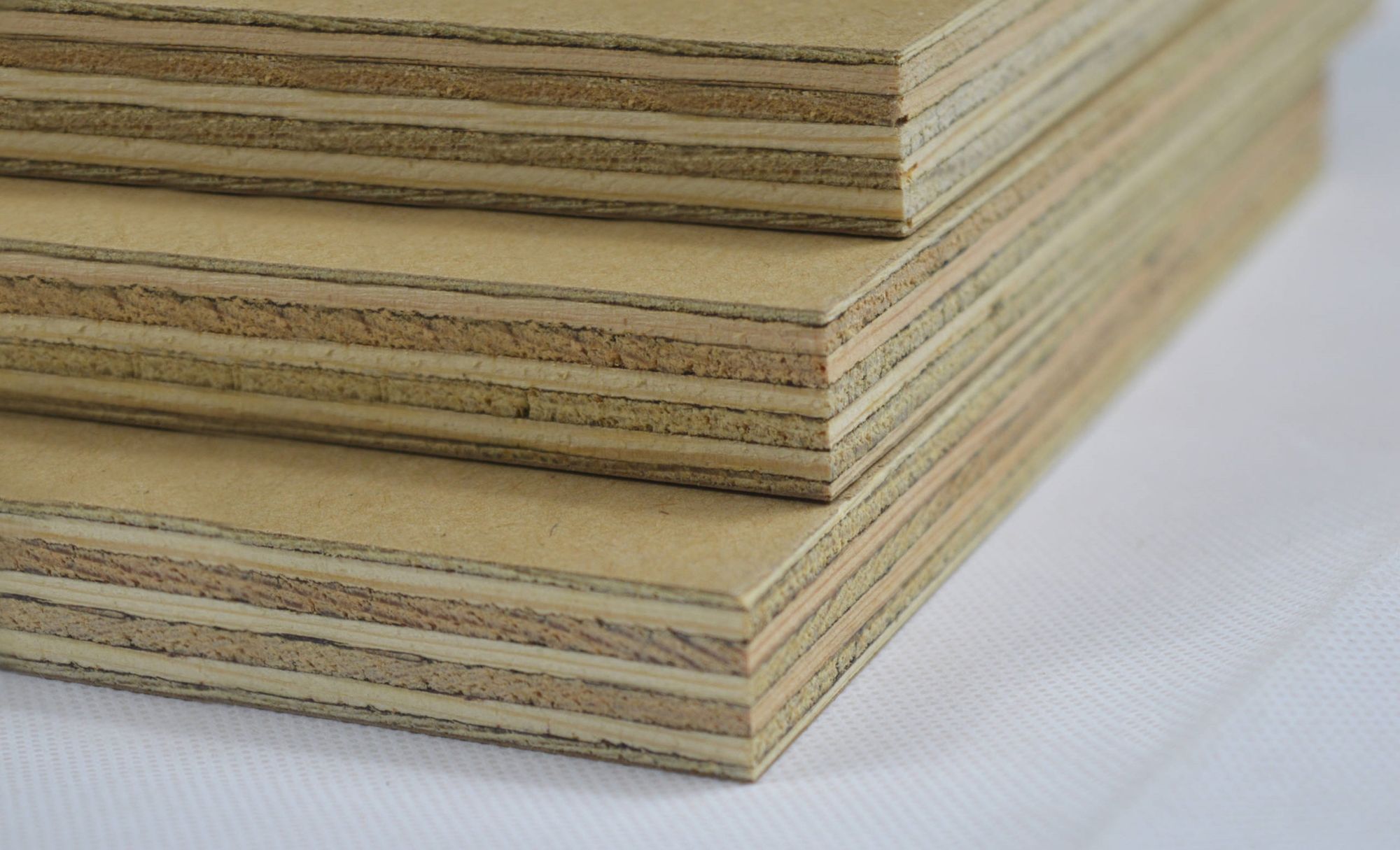

MDO stands for medium density overlay—it’s a type of plywood used for exterior signs, and is more than sufficient for interior signs as well. ‘Medium density’ means the plies are compressed tighter and adhered with stronger glues than your average cheap sheet of plywood, while ‘overlay’ refers to the smooth sheet of resin-impregnated paper that is glued to the face of the plywood.

MDO can be purchased single-sided (paper only on one side) or double-sided. Common thickness options are ½ and ¾ in (1.3 and 1.9 cm). I use ½ in (1.3 cm) for signs intended for mounting on a wall, and ¾ in (1.9 cm) for signs that stand alone, eg A-Frames or sandwich boards.

Specialist lumber yards carry MDO, but general hardware stores like Home Depot and Lowe's do not.

How is MDO different from MDF?

MDF stands for medium density fibreboard; it’s made from wood fibres and resin bonded together and compressed into sheets. MDO, on the other hand, has a plywood core with paper surfaces that contain more resin, making it suitable for outdoors. It is also lighter and stronger than MDF, but more expensive.

Preparing a Sign Blank for Lettering

Here are the steps—as taught by Doc Guthrie at Los Angeles Trade Tech—to turn MDO into a sign blank ready for painting and lettering. The whole process including dry time takes about three days.